Product Advantage:

-

Flexible Well

Flexible well,New product development does not need to re-open mold, greatly shorten the development time of new products, reduce the cost of development.

-

High Speed

For carbon steel, stainless steel, copper, aluminum and other metal materials into high speed, high quality laser cutting.

-

High Precision

Fast speed, High precision, what you see is what you get.

-

A molding

One - time molding, avoid cutting off traditional processing, grinding and other processing processes, save cost, improve efficiency.

Product configuration:

-

The bed is strictly heat-treated.

-

The main engine adopts Japan Ankawa motor, 4 servo motors in total.

-

Interactive cutting table, fast exchange speed, higher cutting efficiency.

-

All screw holes above 4mm of the whole bed are planed by COLGAR large milling machine.

-

The whole machine adopts electric timing oil pot

Strong recommendation: affordable price, strong performance, suitable for optical fiber laser cutting demand is relatively large enterprises to choose to buy.

Friendly tip:optical fiber laser cutting equipment is plate cutting equipment, if you need tube plate all-in-one machine, please visit the website tube plate all-in-one machine or tube all-in-One machine series.

Schneider Circuit Breaker

Schneider Circuit Breaker Taiwan HiWin Guide Rail, Pinion Rack

Taiwan HiWin Guide Rail, Pinion Rack Professional Laser Processing System

Professional Laser Processing System Japan SMC Proportional Valve

Japan SMC Proportional Valve High Performance Servo Motor

High Performance Servo Motor High Precision Reducer

High Precision Reducer Domestic/Imported Laser Source

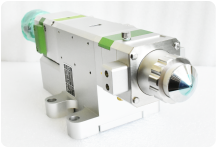

Domestic/Imported Laser Source Import Autofocusing Laser Head

Import Autofocusing Laser Head

ACME laser products

ACME laser products