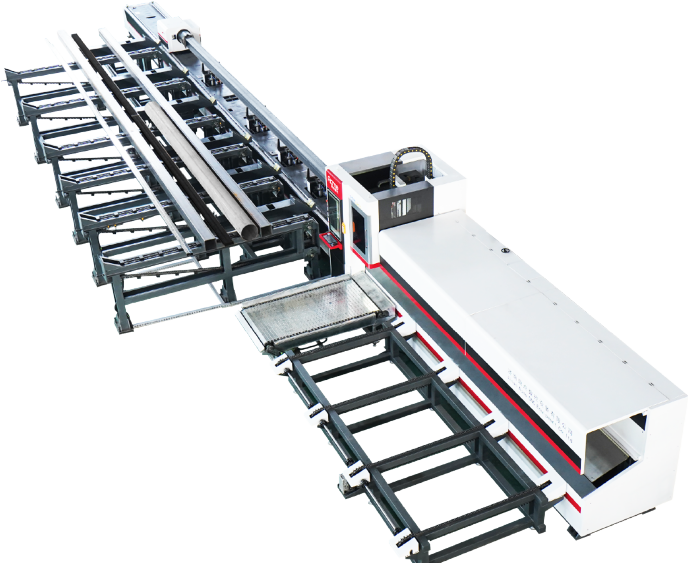

- LT-12035EA laser pipe cutting machine is a super long and heavy equipment independently developed by ACME Laser;

- The bed is made of steel plate and pipe cutting and welding, and the main components such as the bed and chuck are independently developed, designed and produced by our company.

- The equipment is equipped with a full-stroke pneumatic chuck, and the automatic feeding and unloading system is mainly used for cutting, molding and discharging of metal pipes. It is suitable for all kinds of metal pipes with 16-350mm diameter and arbitrary shape.

-

High Performance Servo Motor

High Performance Servo Motor -

High Precision Reducer

High Precision Reducer -

Schneider Circuit Breaker

Schneider Circuit Breaker -

Domestic/

Domestic/

Imported Laser Source -

Professional Laser Processing System

Professional Laser Processing System -

Japan SMC Proportional Valve

Japan SMC Proportional Valve -

Import Autofocusing Laser Head

Import Autofocusing Laser Head -

Touch-controlled Large Screen Display, Real-time Monitoring Equipment Production And Processing Process

-

12m Automatic Feeding Device

-

Full Automatic Discharging Device

To download the

To download the