Product Alerts

-

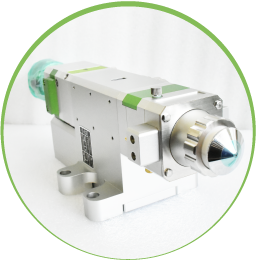

Import Autofocusing Laser Head

Import Autofocusing Laser Head -

High Performance Servo Motor

High Performance Servo Motor -

Domestic/Imported Laser Source

Domestic/Imported Laser Source -

Schneider Circuit Breaker

Schneider Circuit Breaker -

自动上料机构,高效稳定

LT-6012M laser pipe cutting machine is independently developed by ACME Laser. The bed is made of steel pipe cutting and welding, and the bed chuck and other main components

Are independently developed, designed and produced by our company.The equipment is mainly used for cutting, which is suitable for with 16-240mm Diameter round tube

Are independently developed, designed and produced by our company.The equipment is mainly used for cutting, which is suitable for with 16-240mm Diameter round tube

To download the technical

To download the technical