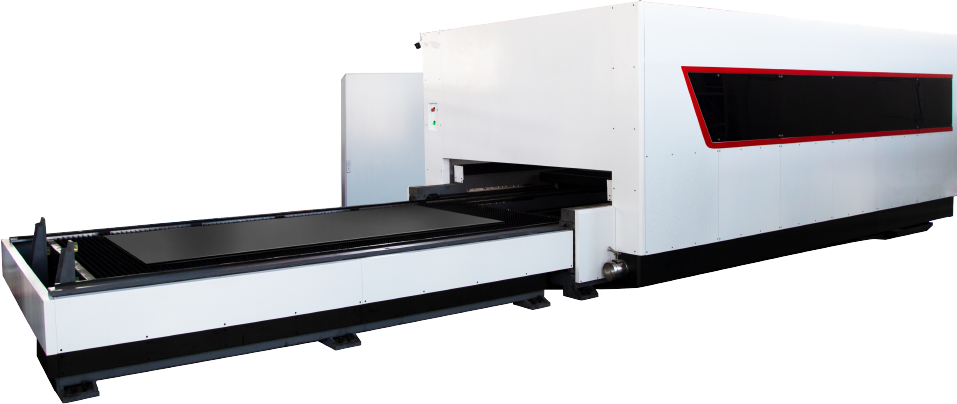

ACME Laser with simple and compact structure.

Split type design of electric control cabinet and bed;

Touch-controlled large screen split display can monitor the production and processing of equipment

The beam is cast by aviation aluminum, the servo motor,

rack and pinion, reducer, electronic components

and other core components are all imported products.

-

Schneider Circuit Breaker

Schneider Circuit Breaker -

Taiwan HiWin Guide Rail, Pinion Rack

Taiwan HiWin Guide Rail, Pinion Rack -

Domestic/Imported Laser Source

Domestic/Imported Laser Source -

Professional Laser Processing System

Professional Laser Processing System -

Japan SMC Proportional Valve

Japan SMC Proportional Valve -

High Performance Servo Motor

High Performance Servo Motor -

High Precision Reducer

High Precision Reducer -

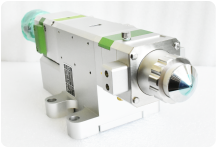

Import Autofocusing Laser Head

Import Autofocusing Laser Head -

Separate Design Of Electric Control Cabinet And Bed

-

The Beam Is Cast In Aeronautical Aluminum

-

Touch-controlled Large Screen Display, Real-time Monitoring Equipment Production And Processing Process

To download the

To download the