-

Intelligent Full Travel Chuck

Independent research and development of the full stroke chuck, no manual adjustment;

Intelligent pressure feedback system, according to different pipe diameters and thicknesses automatic pressure adjustment intelligent identification and holding of all kinds of pipe, real-time detection and alarm, safe and efficient visible.

-

The Laser Head Automatically Avoids Obstacles

Reduce the probability of laser head touching the plate, increase production capacity, improve work efficiency;

-

The Beam Is Cast By Aero - aluminum Pressure

Bed independent research and development, the overall design.The imported processing center is integrated to ensure the one-time processing and molding of the guide rail and rack surface and ensure the accuracy.Stable aseismic, good rigidity, high precision.Super long service life, decades without deformation.

High Precision Reducer

High Precision Reducer High Performance Servo Motor

High Performance Servo Motor Taiwan HiWin Guide Rail, Pinion Rack

Taiwan HiWin Guide Rail, Pinion Rack Japan SMC Proportional Valve

Japan SMC Proportional Valve Professional Laser Processing System

Professional Laser Processing System Schneider Circuit Breaker

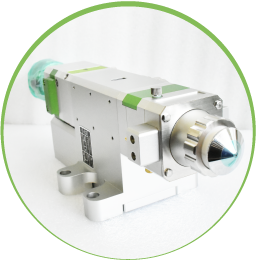

Schneider Circuit Breaker Import Autofocusing Laser Head

Import Autofocusing Laser Head

To download the

To download the