Product Vdvantage:

-

Flexible Well

Flexible well,New product development does not need to re-open mold, greatly shorten the development time of new products, reduce the cost of development.

-

High Speed

For carbon steel, stainless steel, copper, aluminum and other metal materials into high speed, high quality laser cutting.

-

High Precision

Fast speed, high precision, what you see is what you get.

-

A Molding

One - time molding, avoid cutting off traditional processing, grinding and other processing processes, save cost, improve efficiency.

Product Configuration:

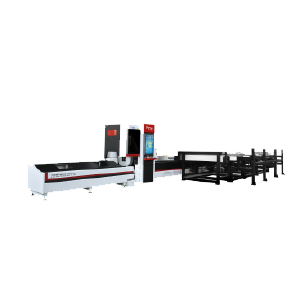

该款光纤切管机又可以称作管材激光切割机、型材激光切割机,可对于圆管、

方管、矩形管、型材、角铁、槽钢、H钢等所有型材金属材料进行精细切割加工。

该款激光切管机配置简介:

- 1The main machine adopts thick wall steel tube and steel plate welding, strict heat treatment.

- 2Adopt self - developed full - stroke automatic centering chuck.

- 3Servo follow - up support design, more stable cutting.

- 4The whole bed and the screw holes above 4mm are all planed and milling by imported large milling machine.

- 5The whole machine adopts electric timing oil pot, which can reduce the equipment loss caused by the failure of lubrication.

- 6Equipped with automatic feeding system, save labor cost, improve processing efficiency.

Strong Recommendation:

The optical fiber CNC pipe cutting machine affordable,

strong performance, welcome to consult the purchase.

Japan SMC Proportional Valve

Japan SMC Proportional Valve Professional Laser Processing System

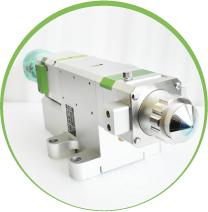

Professional Laser Processing System Import Autofocusing Laser Head

Import Autofocusing Laser Head High Performance Servo Motor

High Performance Servo Motor High Precision Reducer

High Precision Reducer High Precision Reducer

High Precision Reducer Schneider Circuit Breaker

Schneider Circuit Breaker

To download

To download